- The Company

- Articles

- Coalescer Gas Liquid Separator Designs

- Comparison of Centrifugal and Vane Style Gas Liquid Separators

- Design & Capabilities of Gas Liquid Separators

- Differences of a Knock-Out Drum and Centrifugal Gas-Liquid Separator

- Exhaust Head Design

- How float drain traps work, installation and maintenance

- How to identify a Wright-Ausin Separator

- How to Size a Moisture Separator

- Steam Traps vs. Steam Separators

- Efficiencies of Centrifugal Separators

- Understanding Sizing Factors For Gas/Liquid Separators

- Horizontal

- Vertical

- High Solids

- Coalescer

- Elements

- Exhaust Heads

- Float drain traps

- Liquid level gauges

- Sizing Calculators

- Inquiries

Coalescer Gas Liquid Separators

Fine mist separation (>5 microns) with 99% efficiency

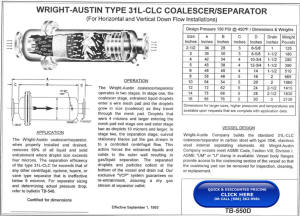

Wright-Austin high efficiency CLC coalescer gas liquid separators can be applied for both horizontal and vertical (up-flow) applications; their compact design often enables them to be installed and supported within the pipeline without costly supports. Whereas standard centrifugal separators have a single vortex stage to remove entrained droplets finer than 10 microns with 99% efficiency, CLC coalescer separators are a two-stage design capable of removing entrained droplets as fine as >5 microns with 99% efficiency. If you require an even finer level of separation, consider our fine mist moisture separators for separation as fine as 0.3 microns. Our article Comparison of Coalescing Gas-Liquid Separator Designs explains both styles in more detail.

The first stage consists of a wire mesh coalescing pad which results in droplets larger than 5 microns to coalesce into droplets larger than 10 microns; the second stage removes droplets larger than 10 microns with 99% efficiency. As with all our centrifugal separator designs, the patented vortex containment plate prevents re-entrainment of the separated droplets and particles after separation.

The mesh layer may require periodic cleaning or replacement, necessitating a flanged body design with stud/nut or swing-bolt closure. Coalescer separators are constructed to ASME code for unfired vessels, Section VIII, Division 1. An ASME stamp and CRN registration can be provided.

Coalescer separators are used in applications where fine mists are encountered in processes involving cooling, condensation, flashing or evaporation. Examples include removal of water or oil from refrigeration gases, steam heated evaporators, compressed air prior to a desiccant dryer bed, high pressure gas at injection wells, fuel gas lines to engines in power and industrial plants, natural gas distribution lines and regulator stations.

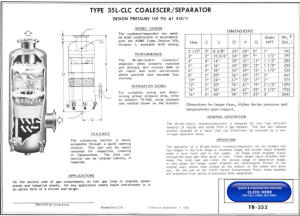

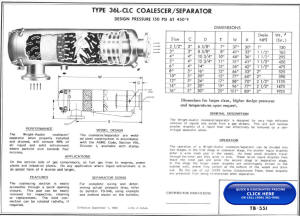

Wright-Austin Coalescing Gas Liquid Separator Outline Drawing Links (click to open full size PDF file)