- The Company

- Articles

- Coalescer Gas Liquid Separator Designs

- Comparison of Centrifugal and Vane Style Gas Liquid Separators

- Design & Capabilities of Gas Liquid Separators

- Differences of a Knock-Out Drum and Centrifugal Gas-Liquid Separator

- Exhaust Head Design

- How float drain traps work, installation and maintenance

- How to identify a Wright-Ausin Separator

- How to Size a Moisture Separator

- Steam Traps vs. Steam Separators

- Efficiencies of Centrifugal Separators

- Understanding Sizing Factors For Gas/Liquid Separators

- Horizontal

- Vertical

- High Solids

- Coalescer

- Elements

- Exhaust Heads

- Float drain traps

- Liquid level gauges

- Sizing Calculators

- Inquiries

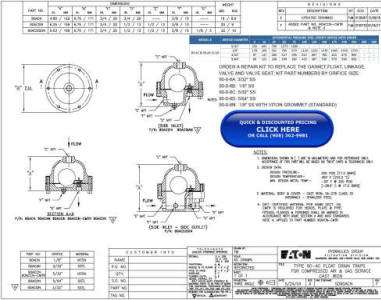

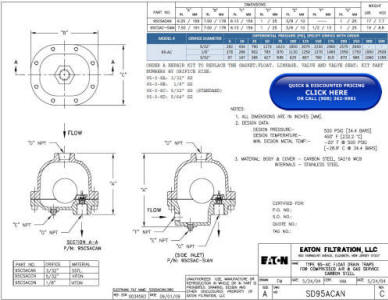

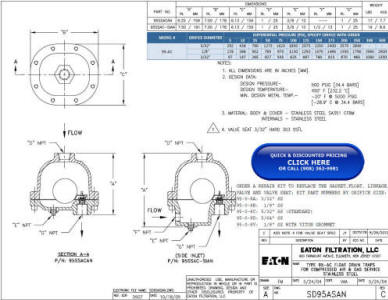

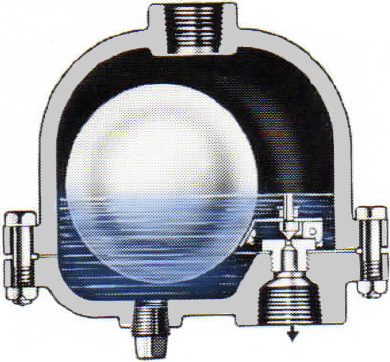

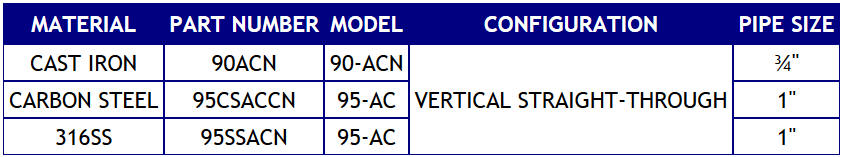

Wright-Austin Model 90-AC and 95-AC

Float Style Drain Traps in Cast Iron, Carbon Steel and 316 Stainless Steel

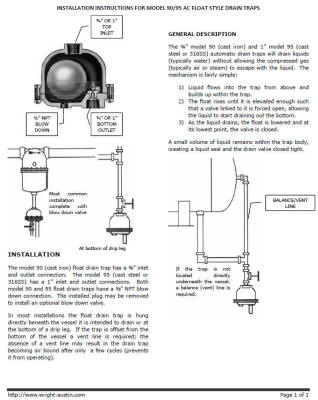

Wright-Austin float style drain traps provide an economical method for draining condensate and fluid from gas/liquid separators for pressures up to 500 PSI without allowing compressed air and steam to escape with it.

Water enters the trap from the topside and builds-up within the trap body. The float rises with the water level and when it gets high enough the float opens a valve. Water is expelled from the bottom and the float quickly comes back down, closing the valve before any air or steam is allowed to escape. A small amount of water remains within the trap, creating a liquid seal and keeping the valve closed tight. Internal parts, including the valve and seat, are corrosion-resistant, non-magnetic stainless steel.

If installed in areas where freezing is a

concern consider ordering a heater to prevent the retained water from

freezing.

• P/N 9014A2, Model 90-AC (for cast iron trap), 50 watt, 120 volt heating

element.

• P/N 9014D, Model 95-AC (for cast steel and 316SS trap), 100 watt,

120 volt heating element.

The components to build float drain traps are usually stocked items and shipments made within 2-3 days to any USA location (7-10 days outside USA) after receipt of an order. If you need assistance with proper selection, please fill-out our inquiry form.

90-AC and 95-AC PDF Outline Drawing and Specificitons Links:

Rebuild Kits for 90/95AC:

(Includes body gaskets for both old and

new style)

Torque specification for body bolts: 255 in-lbs |