- The Company

- Articles

- Coalescer Gas Liquid Separator Designs

- Comparison of Centrifugal and Vane Style Gas Liquid Separators

- Design & Capabilities of Gas Liquid Separators

- Differences of a Knock-Out Drum and Centrifugal Gas-Liquid Separator

- Exhaust Head Design

- How float drain traps work, installation and maintenance

- How to identify a Wright-Ausin Separator

- How to Size a Moisture Separator

- Steam Traps vs. Steam Separators

- Efficiencies of Centrifugal Separators

- Understanding Sizing Factors For Gas/Liquid Separators

- Horizontal

- Vertical

- High Solids

- Coalescer

- Elements

- Exhaust Heads

- Float drain traps

- Liquid level gauges

- Sizing Calculators

- Inquiries

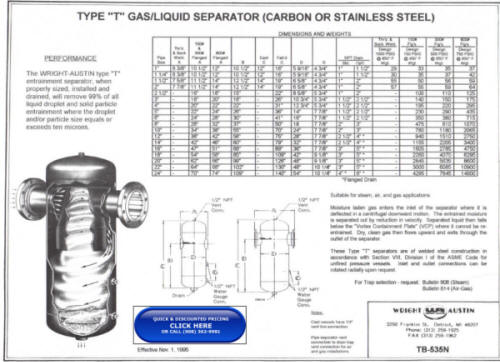

Wright-Austin Type T Gas Liquid Separators

Enhanced Efficiency for Industrial Applications

Enhance separation efficiency with

Wright-Austin Type T gas/liquid separators, meticulously engineered

to meet the demanding needs of industrial processes. Designed to

remove entrained droplets and particles larger than 10 microns with

up to 99% efficiency, our Type T separators offer unparalleled

reliability and performance.

Elongated Design for Enhanced Removal Capacity

The Type T gas/liquid separator features a vertically oriented

cylindrical body, requiring flow path redirection within the

separator. Its elongated body, resembling the letter "T" with

inlet/outlet ports 180 degrees apart, enhances removal capacity,

making it ideal for applications with occasional liquid "slugs."

Variants and Performance

Wright-Austin offers four "T shaped" separator designs: T, TS, R,

and ST, each offering varying levels of entrained droplet removal

capacity. The Type T separator removes entrained droplets equivalent

to 40% of its maximum weight flow capacity, while the Type TS and

Type R variants increase separation rates to 60% and 90%,

respectively.

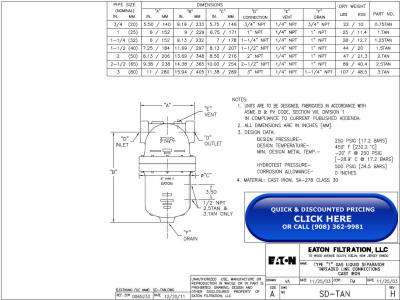

Cast Iron Type T Gas/Liquid Separators

Crafted from durable cast iron, our Type T separators excel in

removing entrained liquid and solids from air, steam, or compatible

gases. Achieving 99% efficiency in removing droplets >10 microns,

these separators boast a maintenance-free design and decades-long

service life. They are particularly suited for steam and compressed

air applications.

Wright-Austin Cast Iron Gas/Liquid Separator Drawings (click to open PDF file):

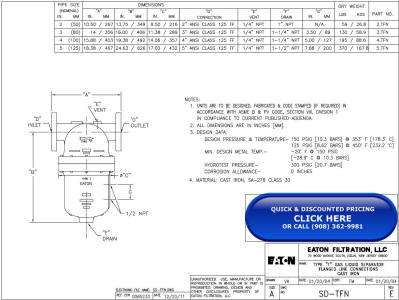

Custom Fabricated Type T

Centrifugal Separators

For specialized applications, our custom fabricated Type T

separators offer versatility and precision. Manufactured using

high-quality materials such as carbon steel, stainless steel, or

other alloys, these separators adhere to ASME Code standards,

ensuring reliability and compliance. With zero maintenance

requirements and fully customizable features, they cater to unique

application needs.

Wright-Austin Fabricated Type T Outline Drawing (click to open PDF file)

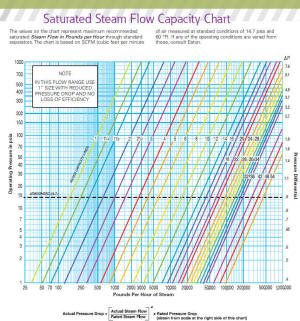

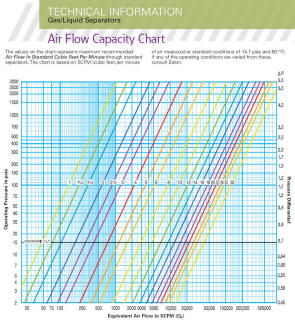

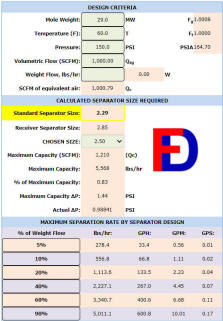

Optimized Sizing and Performance

Determining the optimal separator size is simplified with our

web-based

Wright-Austin Gas/Liquid Separator Sizing Calculator. This

intuitive tool analyzes key parameters such as molecular weight,

temperature, pressure, and design flow, providing quick and accurate

sizing recommendations. Say goodbye to manual calculations and

embrace efficient separation solutions tailored to your specific

requirements.

Sizing Charts,

Formulas and we-based calculator links:

Unlock Enhanced Separation

Efficiency with Wright-Austin

Elevate your gas/liquid separation processes with Wright-Austin Type

T gas/liquid separators. Contact us today (908.362.9981)

to explore our comprehensive range of separator solutions and

experience unmatched performance, reliability, and customer

satisfaction.