- The Company

- Articles

- Coalescer Gas Liquid Separator Designs

- Comparison of Centrifugal and Vane Style Gas Liquid Separators

- Design & Capabilities of Gas Liquid Separators

- Differences of a Knock-Out Drum and Centrifugal Gas-Liquid Separator

- Exhaust Head Design

- How float drain traps work, installation and maintenance

- How to identify a Wright-Ausin Separator

- How to Size a Moisture Separator

- Steam Traps vs. Steam Separators

- Efficiencies of Centrifugal Separators

- Understanding Sizing Factors For Gas/Liquid Separators

- Horizontal

- Vertical

- High Solids

- Coalescer

- Elements

- Exhaust Heads

- Float drain traps

- Liquid level gauges

- Sizing Calculators

- Inquiries

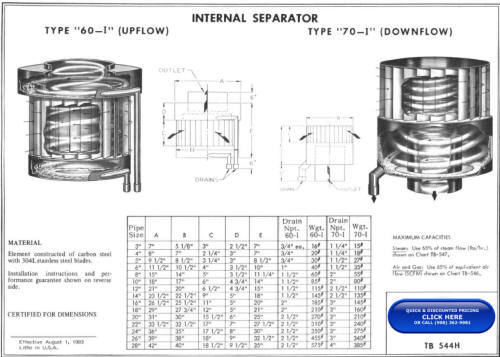

Type 60-I and 70-I Separator Elements

Wright-Austin Type 60-I and 70-I separator elements are for

customers that wish to fabricate their own vessels. The

patented Wright-Austin designs are so efficient that we

routinely supply our internal elements to other manufacturers of

gas/liquid separators!

We can provide our separator elements in carbon steel, stainless

steel or other "exotic" alloys. Our internal elements have

a compact design and require no maintenance because there's no

movable or serviceable parts and by design they are self

cleaning.

As with all of Wright-Austin separators, these elements will

remove 99% of entrained droplets and particulate greater than 10

microns.

We offer two separation element designs, the Type 60-I (left)

for an up-flow exit path and the Type 70-I (right) for down-flow

exit paths. The separation elements create a controlled

centrifugal flow, forcing entrained droplets and particles to

the outer walls of the internal surface area within the element

and drain via an integral drain pipe. We can customize the

elements to suit your specific requirements; examples include

changing the drain size, orientation and length.

Sizing internal separation elements requires using only 65% of

the equivalent air or steam flow based upon their respective

capacity charts. When using with an industrial gas, refer

to the

air capacity chart and make corrections based upon our

corrections factors charts and formulas.

This is the steam capacity chart link. To operate

effectively the separation elements must be located a minimum of

1 foot above the surface of the liquid plus the pressure drop

across the element in inches of water.

As with all of our separation products, we are glad to assist

you with proper sizing and the best way to get started is

completing our

inquiry

form for separators.

Wright-Austin Centrifugal Separator Element Drawings: (click for full size PDF file)